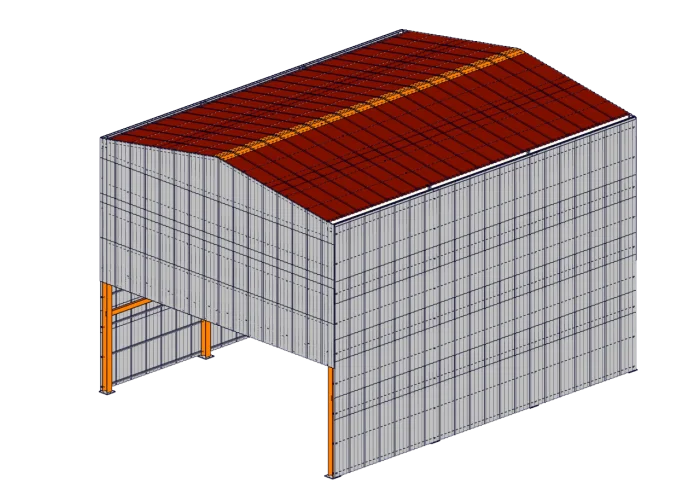

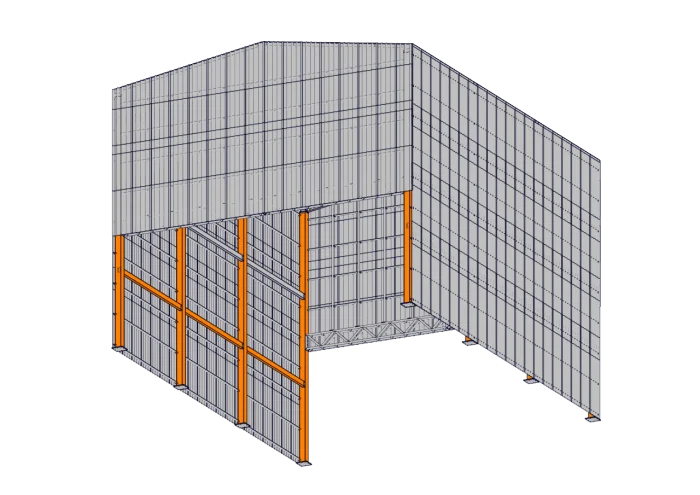

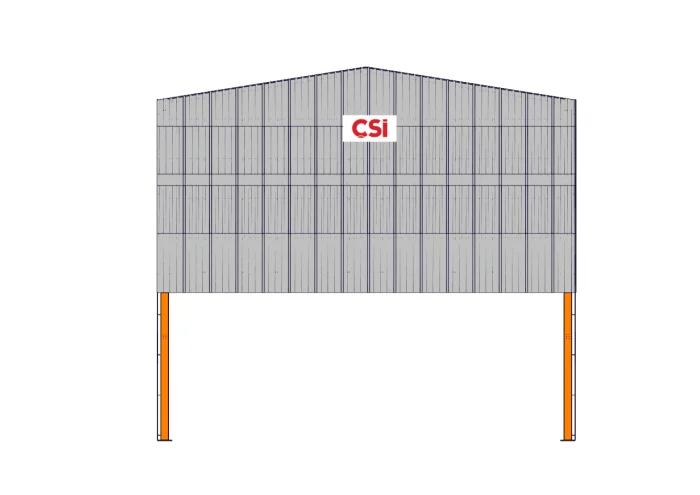

Product Receiving Hangar

Product receiving sheds play a critical role in the agriculture, food processing and logistics industries. These sheds are large, often enclosed spaces where harvested or supplied products are collected, processed and temporarily stored. Here is detailed information about product reception hangars:

What is a Product Receiving Hangar?

Product receiving hangars can be defined as large structures where agricultural products (e.g. grains, vegetables, fruits) are collected, classified, processed and temporarily stored after harvest. These hangars are designed to maintain the quality of products and optimize logistics processes.Usage areas

- Agricultural Products Storage: Areas where harvested products are temporarily stored.

- Sorting and Processing: Facilities where products are sorted, cleaned, and sometimes packaged.

- Logistics and Transportation: Centers where products are collected and loaded onto transportation vehicles before transportation.

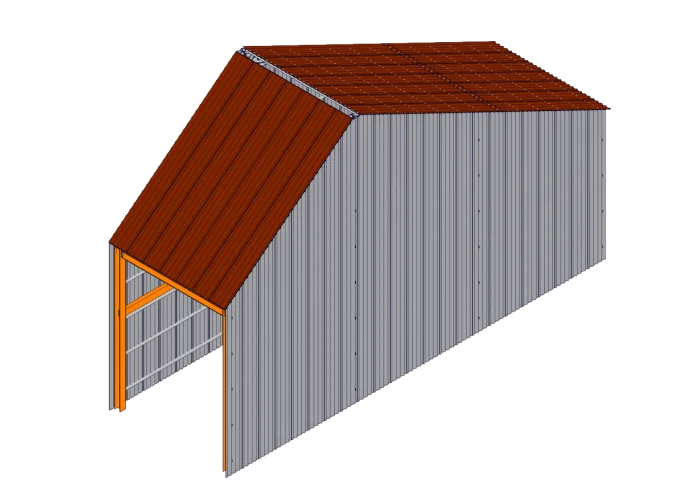

Advantages of Steel Structures

- Durability: Steel structures are durable and long-lasting. It is resistant to harsh weather conditions.

- Easy Installation: Steel hangars can be installed faster and easier than other types of structures.

- Ease of Maintenance: Steel structures require low maintenance and are a cost-effective solution.

- Flexibility: Steel hangars can easily store and process large amounts of products thanks to their wide-span designs.

Key Features

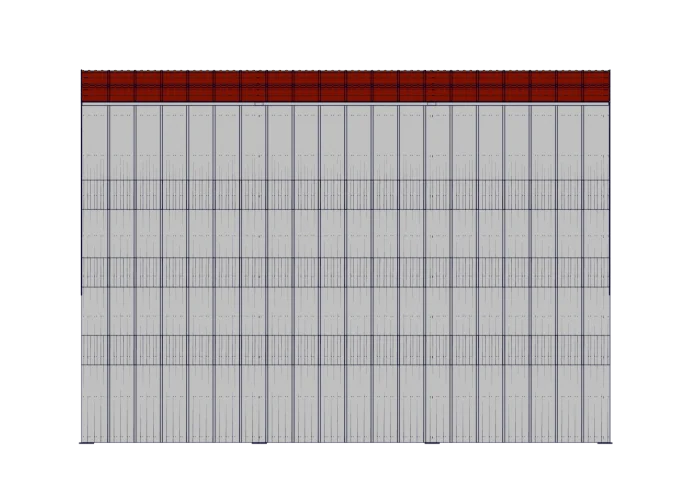

- Large Internal Volume: Provides large space that can accommodate large amounts of products.

- Ventilation and Climate Control: Appropriate ventilation and temperature control systems are in place to maintain the freshness of the products.

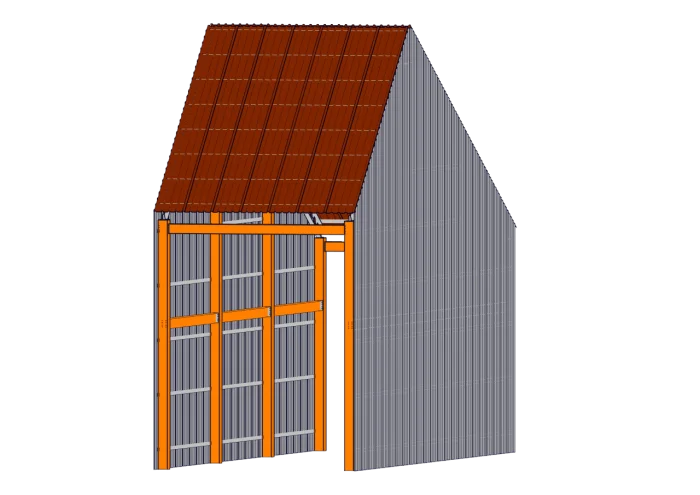

- Easy Access: Equipped with large doors and ramp systems for trucks and other transport vehicles.

- Security: Security systems and fire prevention measures are in place to ensure safe storage of products.

Installation Process

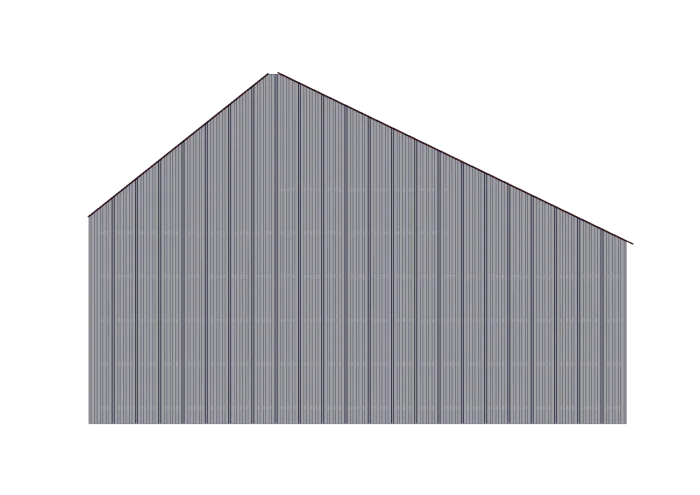

- Planning and Design: The size, capacity and intended use of the hangar are determined.

- Construction Permit and Preparation: Necessary permits are obtained and site preparation is made.

- Foundation Laying: The foundation of the hangar is laid and ground works are completed.

- Assembly of the Steel Structure: Steel structure elements are placed and assembled.

- Internal Equipment and Systems: Ventilation, lighting and other necessary systems are installed.

- Checking and Delivery: The hangar is checked and delivered for use.